durameter hardness test theory|durometer hardness tester : exporting Shore Durometer hardness testing of plastics is described, and conversion charts correlating various scales are presented. The Shore Duromter A and D scales of hardness are commonly used for rubber and 'soft' polymers such as . webServicio Básico y Telefonía Fija Ilimitada incluido. 20% de descuento por 3 meses. Exoneración tasa de conexión en web. 2.577 mensuales Detalles del plan. PLANOS FIBRA. Suscripción a Disney+ y Star+ incluida. Navegá a 900/200 Mbps de velocidad. 1500 Gigas. WiFi Max con 100% de descuento.

{plog:ftitle_list}

Tipwin har fået en karakter på 4.14 ud af 5 mulige! Og lige nu er et særligt meningsfuldt tidspunkt at prøve Tipwin på, da de altså har et glimrende velkomsttilbud. Du får 100% af en indbetaling på op til 800 kr. Indbetaler du 800 kr., får du altså 800 kr. Der er ingen sag, at få fingrene i din Tipwin bonus. Du navigerer.

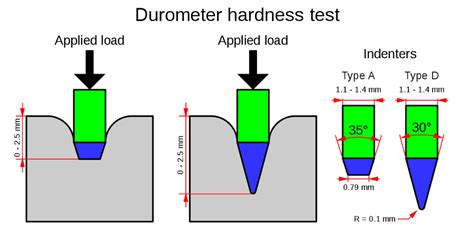

Surface Hardness Indicator. A durometer gage measures the depth of surface penetration for a pin of a predetermined geometry. The device is essentially a machine shop .The Shore D Hardness test is also called Durometer Hardness Test. The letter "D" symbolizes the type of durometer used to measure the hardness of a material. It is a dimensionless .

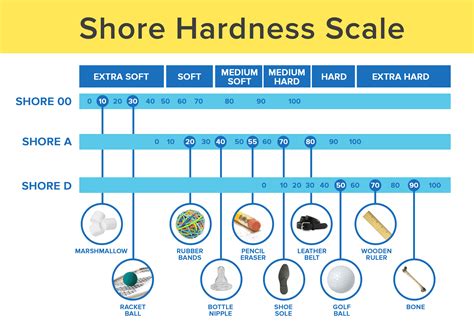

The Shore A hardness (durometer) scale is one of many durometer scales used to measure material hardness. Shore A durometers range from 0 to 100 — the higher the durometer value, the harder the material.Shore Durometer hardness testing of plastics is described, and conversion charts correlating various scales are presented. The Shore Duromter A and D scales of hardness are commonly used for rubber and 'soft' polymers such as . The ASTM D2240 standard outlines the test procedure for measuring the hardness of elastomers using a durometer. The test involves measuring the depth of penetration of a .

The procedure for determining indentation hardness of substances classified as thermoplastic elastomers, vulcanized (thermoset) rubber, elastomeric materials, cellular .Durometer Hardness is used to determine the relative hardness of soft materials, usually plastic or rubber. The test measures the penetration of a specified indentor into the material under .

The Shore D Hardness Scale is a method and reference system for measuring the hardness of materials such as rubber and plastic with a tool called a durometer. The exact measurement points to how much force a .

USA Testing Lab for ASTM D2240 Standard Test Method for Rubber Property-Durometer Hardness in USA, Indonesia, Philippines, Malaysia, Thailand, Canada, China, India, and all over the World. (302)244-7710 . . ASTM D2240 Standard Test Method for Rubber Property-Durometer Hardness. ASTM D2240 encompasses twelve types of rubber hardness . Dr. Dmitri Kopeliovich Shore hardness is a measure of the resistance of a material to penetration of a spring loaded needle-like indenter. Hardness of Polymers (rubbers, plastics) is usually measured by Shore .The Shore D Hardness test is also called Durometer Hardness Test. The letter "D" symbolizes the type of durometer used to measure the hardness of a material. It is a dimensionless quantity. It goes between 0 and 100. The higher number of hardness represents the harder material.

The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is .

Test Shore hardness of rubber and plastics. A Durometer is a material hardness tester for rubber, elastomer, plastic and other similar compounds. They use a specific spring force and indenter shape combination to measure the indentation depth created and the corresponding resistance, according to the ASTM D2240 test standard. Figure 1: Durometer Schematic Surface Hardness Indicator A durometer gage measures the depth of surface penetration for a pin of a . Degrees (IRHD) and durometer are used interchangeably, since the test methods and theory are basically the same. Note, however, that durometer and IRHD will not necessarily be numerically equal. A hardness test uses a limited compressive force to apply a small deformation to the surface of a material, in order to assign a relative value for the material’s hardness. However, a ductility test uses a destructive tensile force to measure the amount of plastic deformation that a material can withstand before breaking.How the test works Shore hardness (also known as 'Durometer hardness') is determined by measuring the penetration of the Durometer's spring loaded indenter into the sample. The operator applies the instrument to the sample with sufficient contact force, in a consistent manner and without shock. During application the indentation

The geometry of the indentor and the applied force influence the measurements such that no simple relationship exists between the measurements obtained with one type of durometer and those obtained with another type of durometer or other instruments used for measuring hardness. This test method is an empirical test intended primarily for .

Whether you need to test the hardness of metal, plastics, or ceramics, Starrett Hardness Testers are an essential tool for quality control and materials testing in a variety of industries, including manufacturing, aerospace, and automotive. Browse through our diverse product offering. Read through the reference information provided. To perform a Shore durometer hardness test, the device is loaded with an indenter. The indenter is then forced onto a material using a spring that applies a known force. The indentation on the material is then measured. Durometer hardness measurements are conveyed as a number on the Shore scale. There are several types of Shore scales that can .The hardness of plastics is most commonly measured by the Shore® (Durometer) test or Rockwell hardness test. Both methods measure the resistance of plastics toward indentation and provide an empirical hardness value that doesn't necessarily correlate well to other properties or fundamental characteristics.

Abstract. Polymer durometry is the measurement of the hardness of plastic and rubber materials using an indentor. Many different hardness scales and indentor geometries have been standardized for durometry. Indentation into a solid is governed by linear elastic mechanics, and this paper relates the Young’s modulus to standardized hardness scale reading. We .

The Durometer is a popular instrument for measuring the indentation hardness of rubber and rubber-like materials. The most popular testers are the Model A used for measuring softer materials and the Model D for harder materials.

How Do You Measure Shore Hardness. The Shore Scale was created by Albert Shore back in the 1920s. He was a metallurgist and is credited as the founder of the durometer, which is the instrument used to measure .Test the hardness of thin and irregularly shaped plastic, rubber, and laminate parts, such as O-rings. These testers can be used on products where the surface area is too small for accurate durometer readings with a standard Shore A tester, such as the rounded surface of O-rings. They include O-ring fixtures that hold five standard-sized O-rings in place during testing.ASTM D2240 durometers allow for a measurement of the initial hardness, or the indentation hardness after a given period of time. The basic test requires applying the force in a consistent manner, without shock, and measuring the hardness (depth of the indentation). If a timed hardness is desired, force is applied for the required time and then .

In this video, an Instrument Choice Scientist demonstrates how to test the hardness of materials using a digital durometer.View the Shore A Digital Durometer.Durometer /Shore hardness Tester. Durometer are used for determining the material hardness of rubber, plastic and other rubber like substance such as neoprene, silicone, vinyl, also be used for soft plastics, felt, leather and similar materials. Shore hardness value in the range from 0 to 100. Maximum penetration for each scale is 2.5 mm.Durometer Operating Stands; Durometer Test Block Kits; Multi-Scale Durometers; O-Ring Hardness Kits; Slim Probe Durometers; Reconditioned Durometers; Data Output Cable . Rex Gauge has been a leader in the durometer hardness gauge industry for over 80 years. Rex Gauge Durometers are available in ASTM D 2240 durometer types (Shore hardness): A .

The Bareiss Digital Durometer – digi test II shore hardness tester is a fully automated hardness testing instrument used to measure Shore, Micro, IRHD (international rubber hardness degree), and VLRH (very low rubber hardness) on a variety of elastomers, foam material. Our digital durometer advanced material testing instrument the highly .Digital Shore Durometer – Shore Hardness Tester– DRIVE Series Key Features: Highest Accuracy and Repeatability: High-resolution sensor and frictionless mechanical construction ensure precise and repeatable measurements. Comprehensive Data: Calculate initial and post-test hardness, measure ambient temperature, specimen surface temperature, and relative . The durometer hardness test results are reported in either Shore A or Shore D scales, depending on the type of material being tested. The Shore A scale is used for softer materials, while the Shore D scale is used for harder materials. The Shore A scale ranges from 0 to 100, with 0 being the softest and 100 being the hardest. .

what is a durometer material

The Shore hardness scale that should be used depends on the test specimen material, while the shape and size of the indenting foot depend on the Shore hardness scale. Lay the test specimen on a hard, flat surface that is ¼” thick or greater. Test the Shore hardness of the material by placing the durometer and its indenting foot against the .

The Shore D hardness scale is a test method that determines the hardness of a material. Learn more about it here. . is a method and reference system for measuring the hardness of materials such as rubber and plastic with a tool called a durometer. The exact measurement points to how much force a material can handle before an indent is created.This is because 40-70 durometer hardness ratings indicate a mid-range rubber hardness. Rubber materials in this range generally very durable and resilient, with excellent physical resistances. 60 durometer rubber in particular is a favorable choice because it can hold up against heavy impacts and abrasions without sacrificing its sturdy form.Welcome to our ASTM D2240 testing services page for evaluating “Shore hardness” as part of our analysis of plastics and polymers.This standard, ASTM D2240, also known as “Rubber Property—Durometer Hardness,” allows for the measurement of a material’s hardness by indenting the material with a standardized tip under a defined force.

special tests for labral tear

squat test for meniscus tear

DESCUIDOS LIVES 😈. 10.8K members. Remoção chamar 👉 @Aqueleze Vamos trocar conteúdo rapaziada 👏 Mandar perfil e indicar as melhores O que acharem mandem ai 🤝 .

durameter hardness test theory|durometer hardness tester